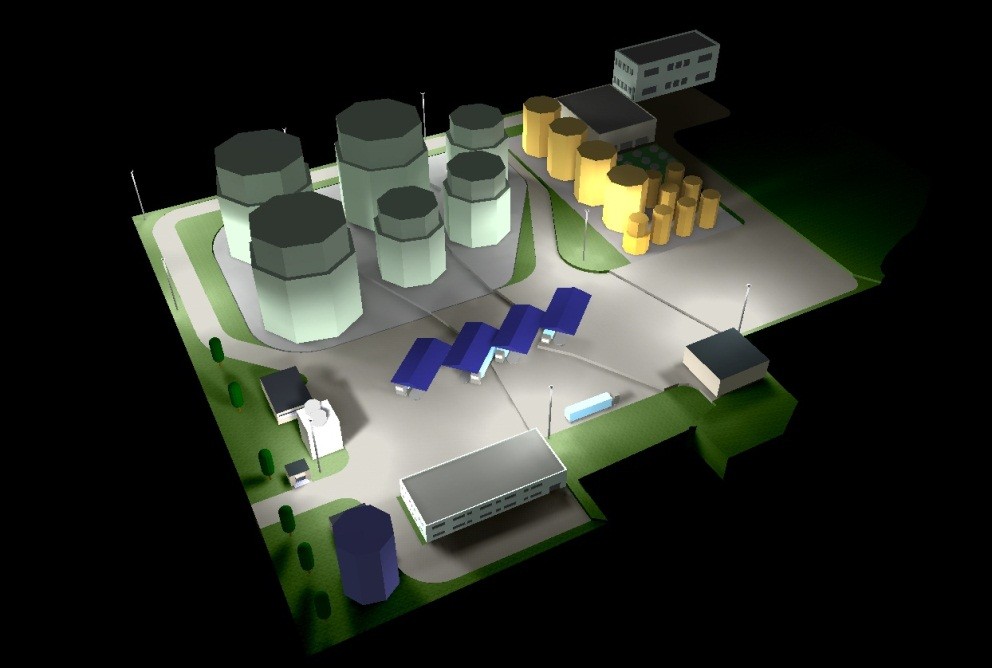

TERMINAL FOR PETROLEUM PRODUCTS VUKOVAR

- Investor: EUROPA MIL ZAGREB

- Vertical storage tanks 12.000 m³

- Truck loading/unloading 100 m³/h

- Wagon loading/unloading 100/150 m³/h

- Ship loading/unloading 150 m³/h at river Dunav

- Infrastructure

- Fire protection system

BIODIESEL PRODUCTION PLANT VUKOVAR

– Investor: EUROPA MIL ZAGREB

– Capacity: 35.000 t/y

– Pressing plant, capacity 3x 720 l/h

– Silo for biomass 2.000 m³

– Storage tanks for raw oil 1.000 m³

– Storage tanks for biodiesel 1.000 m³

– Boiler room 0,6 MW

– Infrastructure

– fire protection system

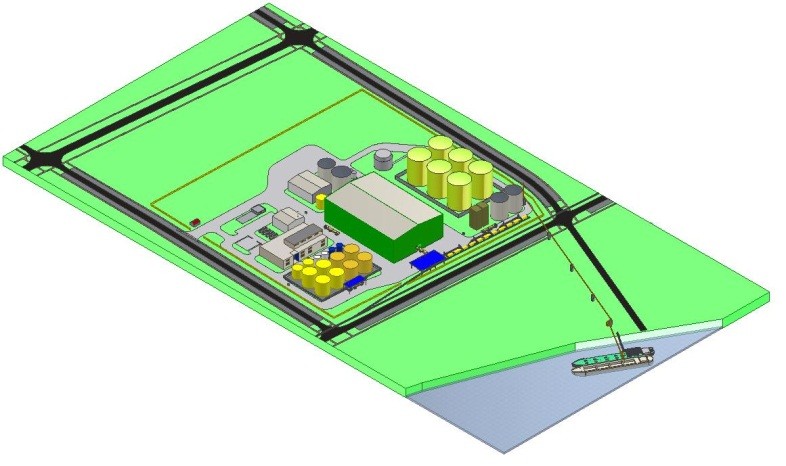

BIODIESEL PRODUCTION PLANT SLAVONSKI BROD

- Investor: INGRA, ZAGREB

- Capacity: 150.000 t/y

- Pressing plant, capacity 60.000 t/y

- Silo for seed 10.000 m³

- Storage tanks for raw oil 52.000 m³

- Storage tanks for biodiesel 32.000 m³

- Truck loading/unloading

- Wagon loading/unloading

- Ship loading/unloading at river Sava

- Infrastructure

- fire protection system

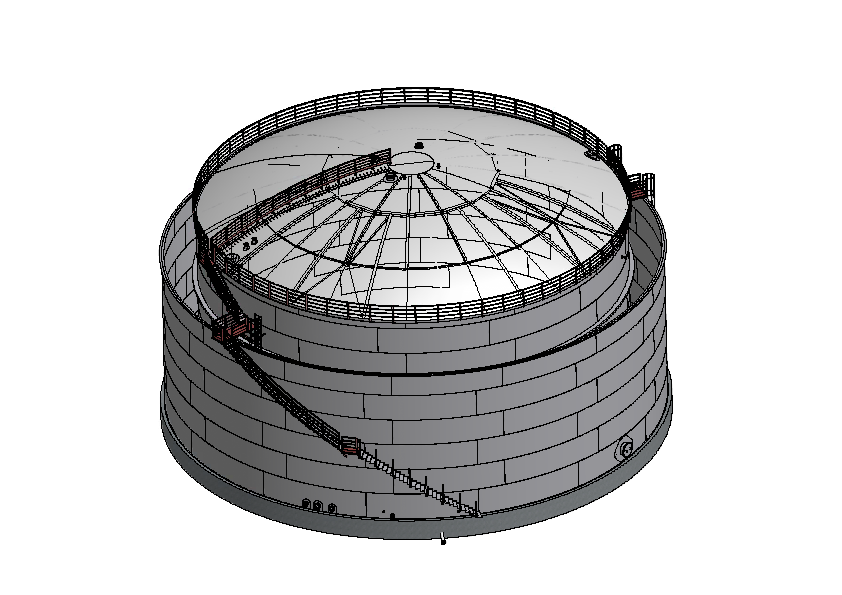

STORAGE TANKS FOR PETROLEUM PRODUCTS - RIJEKA

– Investor: INA Refinery, Rijeka, HYDROKREKING 332

– S1: V=10000 m3, D/D1=30,48 m/ 35,48m, H/H1=14,64 m/11,712m

– Medium: heavy gas oil, vacuum gas oil, heavy coker gas oil

– S2: V=10000 m3, D/D1=30,48 m/ 35,48m, H/H1=14,64 m/11,712m

– Medium: heavy gas oil, vacuum gas oil, heavy coker gas oil

– S3: V=5000 m3, D/D1=22 m/27m, H/H1=13,5 m/10,08m

– Medium: light gas oil, light cyclic oil, light coker gas oil

– S3: V=5000 m3, D/D1=22 m/27m, H/H1=13,5 m/10,08m

– Medium: light gas oil, light cyclic oil, light coker gas oil

– Technology pipelines system included

-pipe 12“ ASME B36.10, ASTM A106Gr.B, 296 m

-pipe 10“ ASME B36.10, ASTM A106Gr.B, 418 m

-pipe 8“ ASME B36.10, ASTM A106Gr.B, 120 m

-pipe 6“ ASME B36.10, ASTM A106Gr.B, 491 m

-pipe 4“ ASME B36.10, ASTM A106Gr.B, 68 m

-pipe 3“ ASME B36.10, ASTM A106Gr.B, 301 m

-pipe 2“ ASME B36.10, ASTM A106Gr.B, 918 m

– Year of project design work: 2009

– Infrastructure

– fire protection system

KEPOL TERMINAL Ltd. ZADAR

OIL DERIVATES STORAGE SPACE WITH ROAD LOADING/UNLOADING SPOT:

- Storage and loading of raw materials (liquids) and finished products

- Tank V = 15000 m3 – 3 pcs

- Tank V = 5000 m3 – 3 pcs

- Cistern unloading with roof – 4 islands with two unloading spots

- Unloading station – 8 draws, 100 m3/h and 1 draw of 500 m3/h

- Oil derivates pipeline – DN 400, 1265 m

- – DN 250, 220 m

- Recuperation of fuel steam

- Drainage system for technology pipelines – slop dish V = 80 m3, drainage pipes

- Fire protection water tank V = 2300 m3

BOILER ROOM AND GAS INSTALATION

- Investor: KEPOL TERMINAL Ltd. ZADAR

- Warm water cauldron Q = 1300 kW

- Warm water cauldron Q = 850 kW

- Steam cauldron Q = 3500 t/h

- Underground storage UNP V = 100 m3

- Gas installation

- Installation of heating pipes and over ground tanks

- Installation of steam pipes for biodiesel production needs

Jetty – PORT ZADAR

- Marine load-discharging hand for oil derivates overload

- Hydraulic impact absorption system

- Capacity – 1350 m3/h

Year 2009

BIOGAS PLANT “Kućanci”, 490 KW

- Complete project documentation, obtaining of construction permit, year 2014.-2016.

- Construction oversight, test drive

- Biogas plant for production of heat and electrical energy consists of one dosage storage tank, one fermentor with gas storage, pumping station, control center, machine room, all infrastructure and necessary depots.

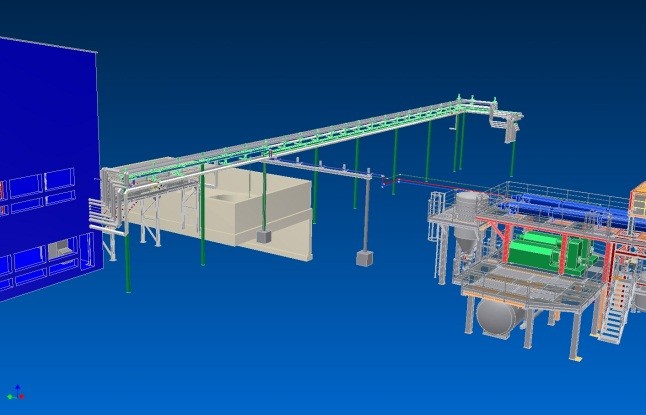

MODERNIZATION OF WAGON LOADING/UNLOADING STATION – INA Refinery, Rijeka

- Design of new wagon loading and unloading spot “VP5” with on-spot loading system including:

- Pumping station

- Technological pipelines

- Fire protection station

- Electrical installations, lightning and grounding

- Measurement, regulation and control system

- Outside hydrant network

- Existing electrical substation reconstruction

- Reconstruction of existing wagon loading and unloading spot “VP1” and “VP2”, construction of new “VP4” including:

- SKID unit for biocide dosing

- Fire protection system reconstruction

- New fire protection system for “VP4”

- Electrical installations, lightning and grounding

- Measurement, regulation and control system

- Vapor recovery unit including: container for VRU, air preparation, technology pipelines, electrical system, instrumentation and control, fire protection

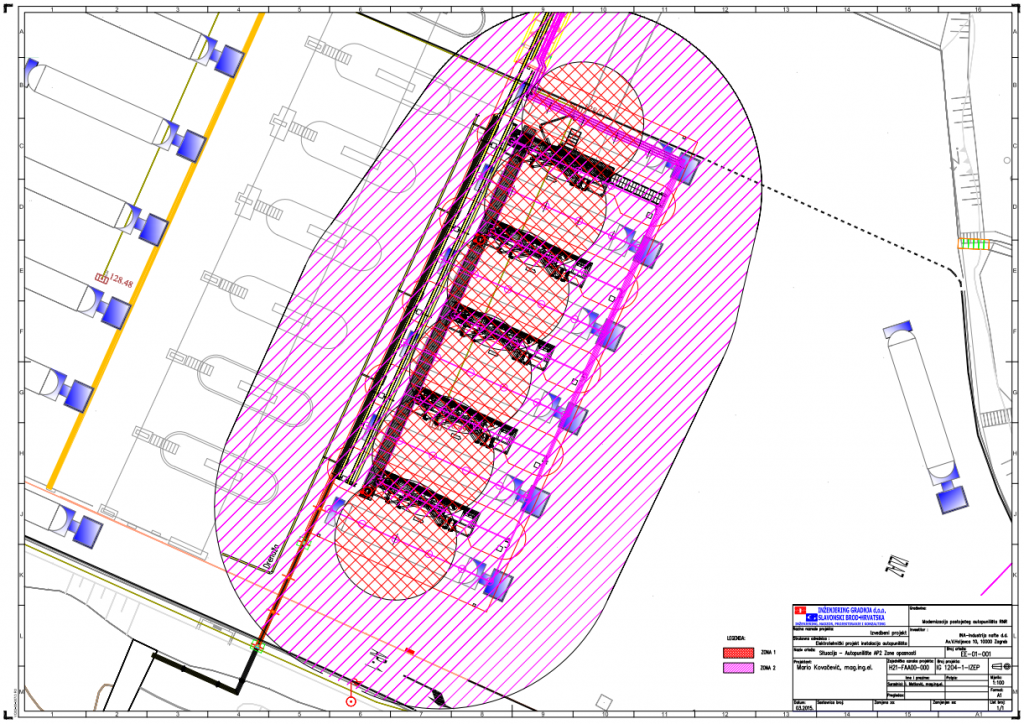

MODERNIZATION OF EXISTING TANK TRUCK LOADING STATION – INA Refinery, Rijeka

- Designing of modernization for tank truck loading station “AP1” and “AP-4”

- Implementation of measurement lines and connection to COTAS system

- Total reconstruction of tank truck loading station “AP2” with new measurement lines and VRU

- Vapor recovery unit

- Reconstruction of existing pumping station

- Road infrastructure for tank cistern manipulation

- Fire protection system

- Electrical distribution, lightning and grounding

- Measurement, regulation and control system

OIL STORAGE, TRUCK LOADING AND GAS STATION “RIJEKATRANS”

- Complete project design, obtaining of permits, test drive, owners engineer and consultin

- Consists of:

- Control building

- Underground fuel storage tank farm

- Truck loading station

- Fuel pumping station